Carton quality from the perspective of ink printing

- PinLong

- 2023/08/09

- 175

- DIGITAL PRINTER SLOTTER

- BOX MAKER

- HIGH GRAPHIC PRINTER VARNISH DRYER

- HIGH SPEED COMPUTERIZED PRINTER

- AUTOMATIC PRE-FEEDER MACHINE

As we all know, the key factors affecting product quality are equipment, raw materials, personnel, and the environment. The same is true for the carton packaging industry. In order to build a high-quality brand, many enterprises have spared no expense to update equipment, make great technological progress, strictly control the raw paper entering the factory, sincerely recruit talents from all over the world, and improve the working environment. Those who are interested will also benefit a lot. As a professional manufacturer of corrugated box printing equipment, in this article, we only briefly describe the experience of improving the quality of cartons from the perspective of ink printing.

- Ensure the clarity of printing

First of all, the printing plate should be made of wear-resistant, moderately elastic, and high-quality materials. The thickness of the plates on the same page should be consistent. The thickness of the resin plate should not be less than 4mm, and the thickness of the rubber plate should be 6-7mm. Regardless of whether it is made with negative film or hand-carved, the layout must be neat, the handwriting pattern, the line depth should not be less than 3mm, the arrangement of the text pattern should not be too crowded, the arc should be smooth, uniform in thickness, and the straight line should be straight and smooth . When printing, the ink should be properly lightened, the ink layer of the inking roller should not be too thick, and the pressure of the roller should be moderate. It is better to print evenly and have no obvious dents on the box surface. Do not increase the ink concentration and increase the pressure of the inking roller to improve the printing effect. This will not only fail to achieve the ideal purpose, but will cause ink on the plate and worse printing quality, especially for small characters, complex patterns, and fine lines. Overprinting requires a high-precision layout, and the disadvantages are more obvious; the speed of the printing machine should not be lower than 800 rpm, if it is too low, the ink on the box surface will be uneven, and there will be bottoming. Too fast, the ink is too thick, and the layout is easy to blur. At the same time, it is necessary to prevent paper wool and paper dust from entering the printing machine and sticking to the printing plate. If paper dust sticks to the plate, stop the machine immediately and wipe it clean with a rag dipped in alcohol.

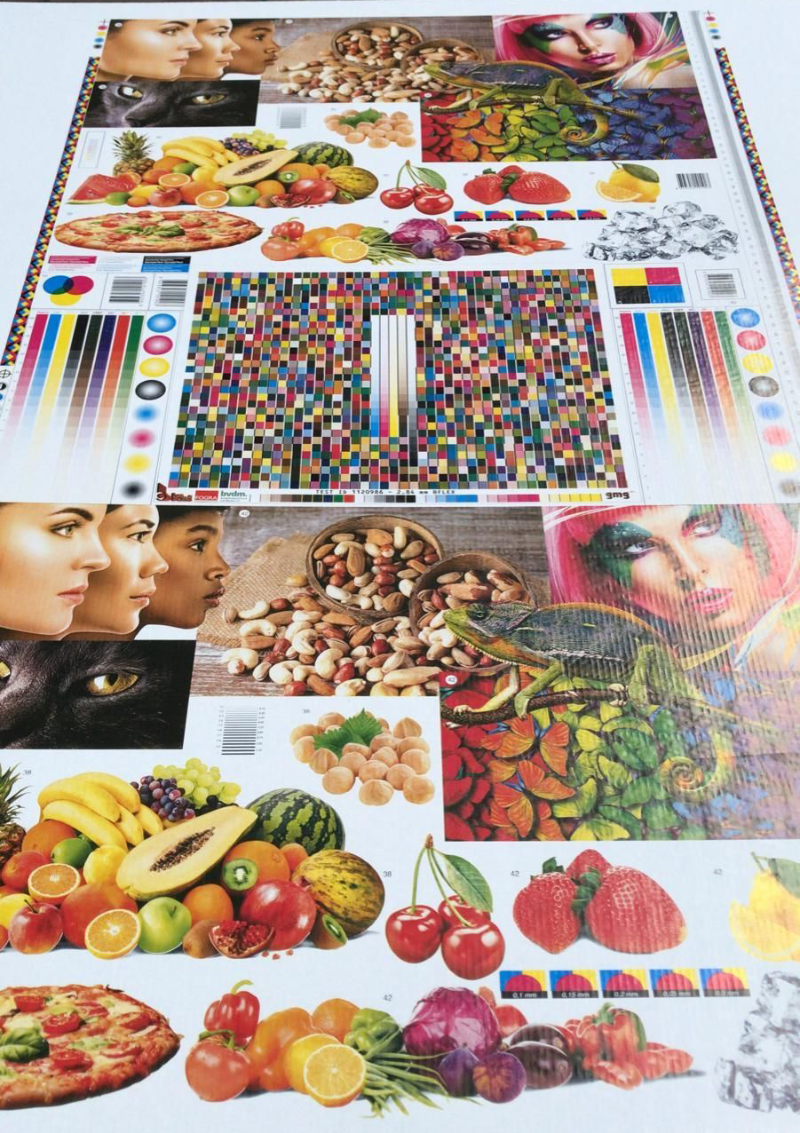

2. The printing color should be pure, with no color difference in batches

The quality of water-based ink is the key to the pure and bright color of carton printing, so we must pay great attention to it when selecting it. There is no obvious difference between the high-quality ink and the color standard. It feels delicate and viscous, and the concentration is suitable for diluting with water or alcohol solvents without precipitation or agglomeration. When stirring with a wooden stick, there is no foam. When mixed with other inks, it has a good affinity and is comparable to each other. Dissolution phenomenon, the color of the prepared ink is pure, and there is no abnormal reaction. Otherwise, it cannot be used.

When printing, it is best to print in batches at one time, otherwise, even if the same bucket of ink is used, there will be color differences. The reason is that after the original ink is diluted with water or alcohol solvent, it is not sealed and exposed to the air for a long time. The chemical components in the ink react with the oxygen in the air, which reduces the pigment, and at the same time, strong light also decomposes the ink.

3. Prevent overprinting and ghosting during printing on coated whiteboard cartons

During the manufacture of coated whiteboard paper, the coating liquid used to coat the whiteboard contains glue, and a small amount of glazing wax is applied to the surface of the high-grade whiteboard paper, so when printing the carton with a whiteboard as the face paper, the printing plate and the whiteboard paper There is slippage at the moment of contact. In addition, the pressure of the printing plate is too heavy, the water-based ink is not easy to penetrate, and the printed carton ink dries slowly. During printing, continuous operation, overlapping, and stacking of printed products, scratches on the box surface form superimposed ghosting.

To solve this problem, the ink should be diluted with ethanol instead of water because it is not easy to volatilize, which is not conducive to the drying of the ink; the printing pressure should be appropriately reduced, and the printing speed should not be too fast, preferably any more than 600 rpm. Install an exhaust fan or ventilate hot air to dry the ink on the box surface before stacking the printing machine.

4. Ensure the accuracy of overprinting

The overprinting accuracy firstly depends on the precision of the equipment and whether the adjustment of the cardboard in the paper feeding part is parallel, and secondly, the layout making, assembly and correction. The following is a brief discussion on the overprinting accuracy in terms of layout collage.

After the printing plate is ready, take a 0.5mm thick transparent polypropylene plate base, draw a vertical line in the center of its length, and then draw the length, width and height lines with a small pen according to the specifications of the carton to be printed, and then press according to the sample draft or sample box The production notice specifies the imposition. After the position of the layout is positioned, draw a line along the edge of the printing plate with a water pen, and then cover the prepared base of the same size on the drawn base, and accurately trace all the edges (if overprinting three colors, draw another base ), and finally according to the overprint color, stick the corresponding printing plate firmly on the painted position with neoprene. Then use double-sided tape to stick the printing plate on the roller of the printing machine. The center line of the plate base and the center line of the plate loading roller of the printing machine can be aligned and coincident. As long as the imposition position is accurate and other objective conditions are met, the overprinting will be accurate.

5. The influence of full-page printing on the strength of cartons

We know that when printing cartons, corrugated cardboard is passed through the paper guide rollers and printing rollers of the printing machine to the grooved part for forming. After the cardboard is pressed by the rollers during the transfer process, its physical properties have changed to varying degrees. Affect the strength of the carton. Full-page printing is particularly prominent. The strength of cartons of the same material is reduced by about 30% compared with those without printing. Therefore, great attention must be paid during the production process, and the following measures can be taken to alleviate it:

First, adjust the gap between the paper guide rollers of the printing machine appropriately, so that the cardboard to be printed passes smoothly without deformation (slightly less than the thickness of the cardboard, 0.1-0.15mm is the best); second, the pressure of the printing plate is adjusted to meet the clear printing , the surface of the box feels free of dents, just flat; third, appropriately increase the speed of the printing machine (above 1000 rpm), so that the cardboard can pass through the printing machine as soon as possible to reduce the pressure time of the cardboard.

6. Timely reprint of carton missing version

Due to the negligence of the operator, the phenomenon of missing characters and missing versions is unavoidable for the printing presses without computer proofreading devices in actual production. Remedial measures should be taken in time after similar incidents occur. If the slotting and cutting corners have not yet been nailed, you can remove the slotting knife, subsidize the missing layout to the corresponding position, and then remove the printing plates of other nozzles to start reprinting. However, do not drive too fast, otherwise it will cause The reprinting effect is not good or the layout is out of place. If the printed carton has been stitched and formed, in addition to the above-mentioned method for the layout, it is advisable to adjust the gap between the guide rollers so that the carton passes through smoothly after forming without deformation. The front baffle is used to determine the position of the layout, and it is conveyed individually during printing.

7. Precautions for printing on thin cardboard

The so-called thin cardboard, that is, D, E fine corrugated cardboard, these thin cardboards should be punched and formed by a flat die-cutting machine after printing, because the batch is small or the customer only does it once, and the cost of the die-cutting knife is high, so the production is difficult. Switch to printing slot forming. In actual operation, because the cardboard is too thin, the printing speed must be slowed down, but the paper pusher is either difficult to push the paper, or pushes multiple sheets of cardboard into the printing machine at the same time, resulting in a lot of waste. To solve this problem, a single machine can be used to slot first, and then print after binding and forming. However, according to the two front and side marks of the carton, it takes two times to print a complete carton.

8. The warped cardboard should be prevented from running, slotting and moving

For warped cardboard printing, use single-sheet feeding and low-speed operation, and at the same time appropriately increase the suction volume, and adjust the slotting phase of the printing plate in a timely manner according to the layout and slotting conditions. The cardboard with serious warping is selected, and every 3-5 sheets of front and back are stacked and flattened with heavy objects before printing next time, or folded flat along the creasing line in the opposite direction of warping and then printed.

In short, specific situations encountered in actual production should be handled flexibly according to objective conditions.

CONTACT US

Guangdong Pinlong Precision Technology Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us